Products

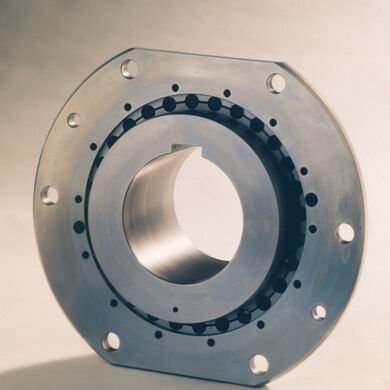

BARREL COUPLING

The NOVOTON® NT... barrel couplings in various designs are recommended for installation in cable drum drives for cranes, winches or conveyors..

Their installation eliminates the occurrence of a statically indeterminate case by making a rigid connection between the gearbox shaft and the drum. This type of mounting requires considerable initial alignment time and even then the detrimental effect on bearings and gears caused by additional stresses due to deformation of housings and wear of running parts cannot be avoided. In the recommended installation, the barrel coupling performs the function of a hinge and makes the connection statically determinate. The hinged coupling behaves as axially free so that the bearing bracket on the opposite side of the drum must withstand the axial forces that may occur. As a special application on request, the barrel coupling can be designed as an axially load-bearing joint itself.

CONSTRUCTION FEATURES

The barrel coupling basically consists of a flange sleeve with semicircular inner teeth, a hub with outer teeth of the same shape and a series of hardened steel barrels which are housed between the two parts. The inner transmission area is sealed by mounting a cover on each side with corresponding seals. Two retaining rings mounted on the hub, one on each side of the teeth, limit the axial displacement of the barrels in their housing. There are 2 different designs available. The basic models called NT-...., in which the retaining rings are in direct contact with the barrels, and the new generation models called NTSG-..., in which thrust washers are installed between the barrels and the retaining rings. The latter comply with the German Steel Standard SEB 666212 (January 1991) (Stahl-Eisen-Betriebsblatt) as well as with the French Steel Standard. The convex shape of the barrels and the internal spaces of the teeth allow an angular misalignment of ±1° and an axial displacement varying from ±3mm to ±10mm depending on the size for angularly aligned position to be accepted in the coupling.

The torque is transmitted to the receiving flange of the drum, usually through two diametrically opposed flat driving faces on the periphery of the coupling flange, which also cooperates with the friction effect of the connecting bolts of both flanges. Other systems, such as tightened bolts or similar, can also be used by preparing the flanges appropriately.

The described design is suitable to support large radial loads, as they are distributed over large bearing surfaces of the barrels, and minimises the alternative bending effect of the torsional torque on the teeth, as these are robust due to their low height and large bottom section. In addition, due to the effect of a "crush polishing" of the hardened barrel on the tooth profile, its wear resistance is significantly improved.